Silk screen printing is a popular method used by various industries to print designs on a multitude of surfaces, including textiles, ceramics, and glass. As a leading company in the field, Woolley Automatic Machinery Ltd, known for our Quicker Tube Machines Manufacturer division, understands the importance of maintaining high-quality prints. However, even the most advanced silk screen printing machines can encounter ink-related issues. This comprehensive guide will help you troubleshoot common ink problems and ensure your printing process runs smoothly.

Before diving into troubleshooting, it's essential to understand the basic principles of silk screen printing. This technique involves using a mesh to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. The process is versatile and can be used for both small-scale and large-scale production.

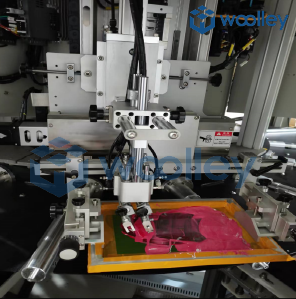

To effectively troubleshoot ink issues, familiarize yourself with the key components of a silk screen printing machine:

Frame and Mesh: The frame holds the mesh, which is the medium through which ink is transferred.

Stencil: The design to be printed is created on the mesh using a stencil.

Squeegee: This tool is used to push ink through the mesh onto the substrate.

Ink: Specialized inks are used depending on the substrate and design requirements.

Substrate: The material onto which the design is printed.

Ink issues can arise from various factors, including environmental conditions, machine settings, and ink quality. Below are some common problems and their solutions:

Tube Extruder Machine JX-EX02 for 2-layer

Laminate Tube Machine JX-LM150

Tube Extruder Machine JX-EX01

Laminate Tube Machine JX-LM100

Offset Printing Machine JX-AC89 for Aluminium Cans

Problem: Ink bleeding occurs when the ink spreads beyond the intended design, resulting in a blurry print.

Solution: To address ink bleeding, ensure that the substrate is compatible with the ink type. Adjust the mesh tension and make sure the stencil is properly adhered to the mesh. Additionally, check the ink viscosity and adjust it according to the manufacturer’s recommendations.

Problem: Inconsistent ink coverage results in uneven prints with some areas appearing lighter or darker than others.

Solution: Examine the squeegee pressure and angle. Uneven pressure can lead to inconsistent ink deposition. Ensure the squeegee blade is in good condition and replace it if necessary. Additionally, check the ink's viscosity and adjust it to achieve uniform coverage.

Problem: Ink drying too quickly can cause clogging of the mesh and incomplete prints.

Solution: Adjust the environmental conditions in the printing area. High temperatures and low humidity can accelerate ink drying. Use retarder additives to slow down the drying process and ensure smooth ink flow.

Problem: Ink not adhering properly can result in prints that easily peel or flake off.

Solution: Ensure the substrate is clean and free of contaminants. Pre-treat the substrate if necessary to improve adhesion. Select an ink that is compatible with the substrate material. Test different curing times and temperatures to find the optimal setting for ink adhesion.

Problem: Colors may appear different from the intended design due to ink mixing or incorrect color settings.

Solution: Use color management software to calibrate the printing process. Ensure that the ink is mixed thoroughly before use. Check the mesh count and stencil thickness, as these can affect color accuracy. Conduct test prints to verify color output before starting full production.

Implementing preventive measures can minimize ink issues and enhance the efficiency of your silk screen printing machine:

Regular Maintenance: Schedule routine maintenance for your machine to ensure all components are in good working condition.

Quality Control: Implement quality control checks at various stages of the printing process to identify and address issues early.

Training: Provide comprehensive training to operators on machine operation and troubleshooting techniques.

Environmental Control: Maintain optimal temperature and humidity levels in the printing area to prevent ink-related issues.

Ink issues in silk screen printing can be challenging, but with a systematic approach, they can be effectively managed. By understanding the components of your silk screen printing machine and the common ink problems that can arise, you can take proactive measures to troubleshoot and resolve these issues. At Woolley Automatic Machinery Ltd, our Quicker Tube Machines Manufacturer division is committed to providing high-quality equipment and support to ensure your printing operations are successful.

For more information on silk screen printing and troubleshooting, feel free to contact our expert team. We are here to assist you with all your printing needs and help you achieve exceptional results.

Remember, consistent quality prints are not just a result of high-quality equipment but also the knowledge and skills of the operators. Stay informed, stay prepared, and ensure your printing process is always at its best.

Contact: Mr. Woolley Tian

Phone: +8613671872020

Tel: +8613671872020

Email: woolley@woolleyauto.com(Вудли)

Add: No. 1379, Jiahao Road, Nanxiang Town, Jiading District, Shanghai City, China.