In the rapidly evolving world of manufacturing and design, the demand for precision, efficiency, and innovation has never been greater. Among the myriad of technologies propelling this progress, extruding tube machines stand out as a pivotal tool in the arsenal of modern manufacturers. Woolley Automatic Machinery Ltd, a leading name in the industry, has been at the forefront of this technological revolution, with their Quicker Tube Machines Manufacturer division setting new benchmarks in the field.

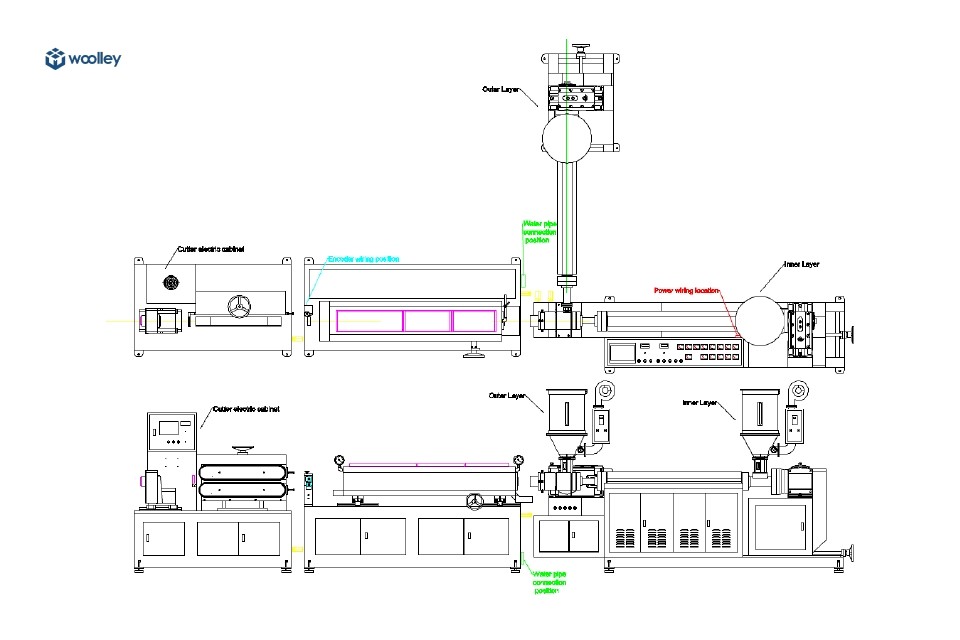

Extruding tube machines are specialized equipment used to create tubes of various materials, including metals, plastics, and composites. The process involves forcing material through a die to create a continuous profile, which is then cut to the desired length. This method is highly efficient, allowing for the production of complex shapes with high precision and minimal waste.

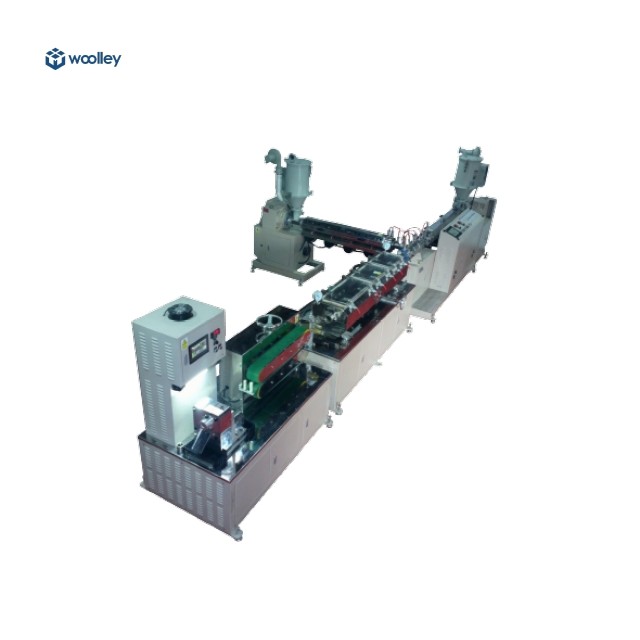

Woolley Automatic Machinery Ltd has leveraged this technology to provide solutions that cater to a wide range of industries, from automotive and aerospace to medical and consumer goods. Their Quicker Tube Machines are renowned for their speed, accuracy, and versatility, making them a preferred choice for companies seeking to enhance their production capabilities.

Extruding tube machines play a crucial role in innovative design by enabling manufacturers to experiment with new materials and complex geometries. This flexibility is essential for industries that require lightweight, durable, and aesthetically pleasing components. The ability to produce custom profiles with tight tolerances opens up new possibilities for designers, allowing them to push the boundaries of what is possible.

One of the key advantages of using extruding tube machines is their ability to produce highly customized products. Woolley Automatic Machinery Ltd has developed machines that can handle a wide range of materials and dimensions, providing designers with the flexibility to create unique solutions tailored to specific applications. This capability is particularly valuable in industries such as aerospace, where weight reduction and structural integrity are paramount.

The efficiency of extruding tube machines translates into significant cost savings for manufacturers. By minimizing material waste and reducing production times, companies can achieve higher output at lower costs. Woolley's Quicker Tube Machines are designed to optimize these efficiencies, offering rapid setup times and seamless integration with existing manufacturing processes.

Quality and precision are critical in any manufacturing process, and extruding tube machines excel in delivering both. The advanced technology employed by Woolley Automatic Machinery Ltd ensures that each tube produced meets stringent quality standards. This reliability is crucial for industries such as medical device manufacturing, where even the smallest deviation can have significant consequences.

The versatility of extruding tube machines makes them indispensable across a wide range of industries. Below are some of the key sectors benefiting from this technology:

Automotive: In the automotive industry, extruding tube machines are used to produce lightweight components that enhance fuel efficiency and performance. From exhaust systems to structural reinforcements, the ability to create complex profiles is invaluable.

Aerospace: The aerospace sector demands components that are both strong and lightweight. Extruding tube machines enable the production of intricate shapes that meet these requirements, contributing to the development of more efficient aircraft.

Medical: Precision is paramount in the medical industry, and extruding tube machines provide the accuracy needed to produce components such as catheters and surgical instruments. The ability to work with biocompatible materials is an added advantage.

Consumer Goods: From furniture to sporting equipment, extruding tube machines allow manufacturers to create aesthetically pleasing and functional products that meet consumer demands.

Woolley Automatic Machinery Ltd has established itself as a leader in the field of extruding tube machines, thanks to its commitment to innovation and quality. The company's Quicker Tube Machines Manufacturer division is dedicated to developing cutting-edge solutions that address the evolving needs of modern manufacturers.

At the heart of Woolley's success is its robust research and development program. By investing in the latest technologies and collaborating with industry experts, the company continuously enhances its product offerings. This focus on innovation ensures that Woolley's machines remain at the forefront of the industry, providing customers with the tools they need to succeed.

Woolley Automatic Machinery Ltd places a strong emphasis on understanding the unique needs of its customers. By offering customized solutions and comprehensive support, the company ensures that its clients can maximize the benefits of their extruding tube machines. This customer-centric approach has earned Woolley a reputation for excellence and reliability.

As technology continues to advance, the role of extruding tube machines in innovative design is set to grow even further. Emerging trends such as additive manufacturing and the use of smart materials present new opportunities for these machines to enhance production processes and enable groundbreaking designs.

The integration of extruding tube machines with Industry 4.0 technologies is a key area of development. By incorporating IoT sensors and data analytics, manufacturers can optimize their operations, predict maintenance needs, and improve product quality. Woolley Automatic Machinery Ltd is actively exploring these possibilities, ensuring that its machines remain at the cutting edge of technological advancements.

As sustainability becomes a priority for manufacturers, extruding tube machines offer a way to reduce environmental impact. By minimizing material waste and energy consumption, these machines contribute to more sustainable production practices. Woolley is committed to developing eco-friendly solutions that align with the goals of its customers and the broader industry.

In conclusion, extruding tube machines are a vital component of innovative design, offering unparalleled flexibility, efficiency, and precision. Woolley Automatic Machinery Ltd, through its Quicker Tube Machines Manufacturer division, is leading the charge in harnessing this technology to meet the demands of modern manufacturing. As industries continue to evolve, the role of extruding tube machines will only become more significant, paving the way for new possibilities and advancements in design.

For manufacturers seeking to stay ahead of the curve, investing in state-of-the-art extruding tube machines from a trusted provider like Woolley Automatic Machinery Ltd is a strategic move that promises to deliver substantial benefits. As the future unfolds, these machines will undoubtedly continue to shape the landscape of manufacturing and design, driving innovation and excellence across industries.

Tags:Auto self-cleaning Machine,Foiling & Capping Machine,Auto Heading Machine

Contact: Mr. Woolley Tian

Phone: +8613671872020

Tel: +8613671872020

Email: woolley@woolleyauto.com(Вудли)

Add: No. 1379, Jiahao Road, Nanxiang Town, Jiading District, Shanghai City, China.