In the world of manufacturing and industrial processes, the tube extrusion machine has emerged as one of the most transformative pieces of equipment. Over the decades, the evolution of this machinery has significantly impacted industries ranging from construction to automotive, healthcare, and beyond. At the forefront of this evolution is Woolley Automatic Machinery Ltd, a globally recognized leader and innovator in the field. Known as the "Quicker Tube Machines Manufacturer," Woolley Automatic Machinery Ltd has consistently pushed the boundaries of what tube extrusion technology can achieve, setting new benchmarks for speed, precision, and efficiency.

This article delves into the history, advancements, and industry-wide implications of tube extrusion machines, with a particular focus on the contributions of Woolley Automatic Machinery Ltd. From humble beginnings to the high-tech solutions of today, the journey of tube extrusion machinery is a testament to engineering ingenuity and industrial adaptability.

Tube extrusion technology traces its roots back to the early 19th century, when the first rudimentary extrusion processes were developed. Initially, the technology was used to create simple lead pipes for plumbing applications. The process involved heating the material and forcing it through a die to create a hollow, cylindrical shape. While effective for its time, these early machines were slow, labor-intensive, and lacked precision.

As industrialization gained momentum in the late 19th and early 20th centuries, the demand for more efficient and versatile tube manufacturing methods grew. This led to the development of more advanced extrusion machines capable of handling a wider range of materials, including aluminum, steel, and various polymers. By the mid-20th century, tube extrusion had become a cornerstone of modern manufacturing, enabling the mass production of pipes, tubes, and other hollow components.

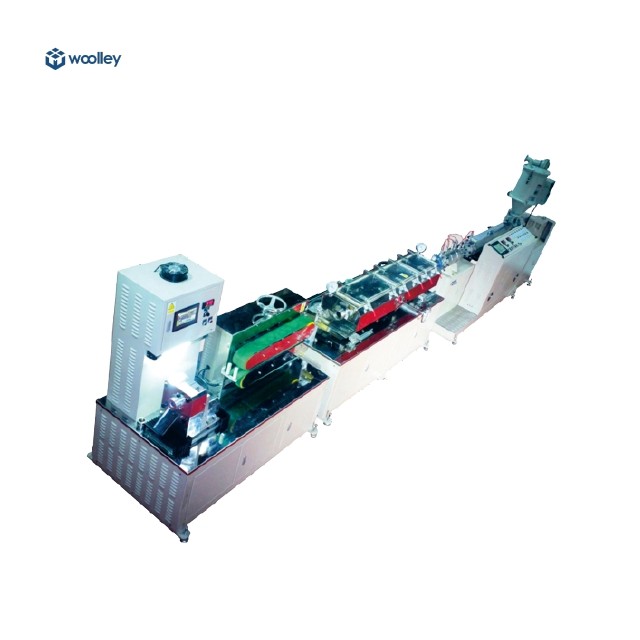

Founded with a vision to redefine industrial machinery, Woolley Automatic Machinery Ltd has played a pivotal role in the evolution of tube extrusion technology. As the "Quicker Tube Machines Manufacturer," the company has introduced groundbreaking innovations that have reshaped the industry. Their machines are renowned for their speed, precision, and reliability, making them the go-to choice for manufacturers worldwide.

One of Woolley's most significant contributions is the integration of automation and digital technology into tube extrusion machines. By incorporating advanced control systems, sensors, and software, the company has enabled real-time monitoring and optimization of the extrusion process. This has not only improved production efficiency but also ensured consistent quality, even for complex and high-volume projects.

High-Speed Extrusion: Woolley's machines are designed to operate at unprecedented speeds, significantly reducing production time without compromising on quality.

Material Versatility: The company's equipment can handle a wide range of materials, from traditional metals to advanced composites and thermoplastics.

Precision Engineering: Advanced die designs and control systems ensure that every tube meets exact specifications, minimizing waste and rework.

Energy Efficiency: Woolley's machines incorporate energy-saving technologies, making them more sustainable and cost-effective.

Custom Solutions: The company offers tailored machines to meet the unique needs of different industries, from automotive to aerospace.

The advancements in tube extrusion technology, spearheaded by companies like Woolley Automatic Machinery Ltd, have had far-reaching implications across multiple sectors. Here are some of the key industries that have benefited:

In the construction industry, tube extrusion machines are used to produce pipes and structural components that are essential for building infrastructure. Woolley's high-speed machines have enabled faster project completion times, reducing costs and improving efficiency. Additionally, the ability to produce customized tubes has allowed architects and engineers to explore innovative designs and applications.

The automotive sector relies heavily on lightweight yet durable materials to enhance vehicle performance and fuel efficiency. Woolley's machines are capable of producing high-precision tubes for exhaust systems, chassis components, and more. The company's focus on material versatility has also facilitated the use of advanced alloys and composites, further driving innovation in the industry.

In the healthcare sector, tube extrusion machines are used to manufacture medical tubing for applications such as catheters, IV lines, and respiratory equipment. Woolley's precision engineering ensures that these tubes meet stringent quality standards, safeguarding patient safety and improving healthcare outcomes.

From oil and gas pipelines to renewable energy systems, tube extrusion machines play a crucial role in the energy sector. Woolley's energy-efficient machines have helped companies reduce operational costs while meeting the growing demand for sustainable solutions. The ability to produce corrosion-resistant tubes has also enhanced the longevity and reliability of energy infrastructure.

The evolution of tube extrusion machines is a fascinating journey that highlights the intersection of engineering, technology, and industry. From their humble beginnings to the high-tech marvels of today, these machines have transformed the way we manufacture tubes, pipes, and other hollow components. Companies like Woolley Automatic Machinery Ltd have been instrumental in this transformation, setting new benchmarks for speed, precision, and efficiency.

As we look to the future, the potential of tube extrusion technology is limitless. With advancements in automation, sustainability, and customization, the industry is poised for even greater achievements. For manufacturers, adopting cutting-edge solutions from leaders like Woolley Automatic Machinery Ltd is not just an option—it’s a necessity for staying competitive in an ever-evolving market.

In conclusion, the impact of tube extrusion machines on industry cannot be overstated. They are more than just tools; they are enablers of progress, innovation, and growth. And with companies like Woolley Automatic Machinery Ltd at the helm, the future of tube extrusion technology looks brighter than ever.

Contact: Mr. Woolley Tian

Phone: +8613671872020

Tel: +8613671872020

Email: woolley@woolleyauto.com(Вудли)

Add: No. 1379, Jiahao Road, Nanxiang Town, Jiading District, Shanghai City, China.