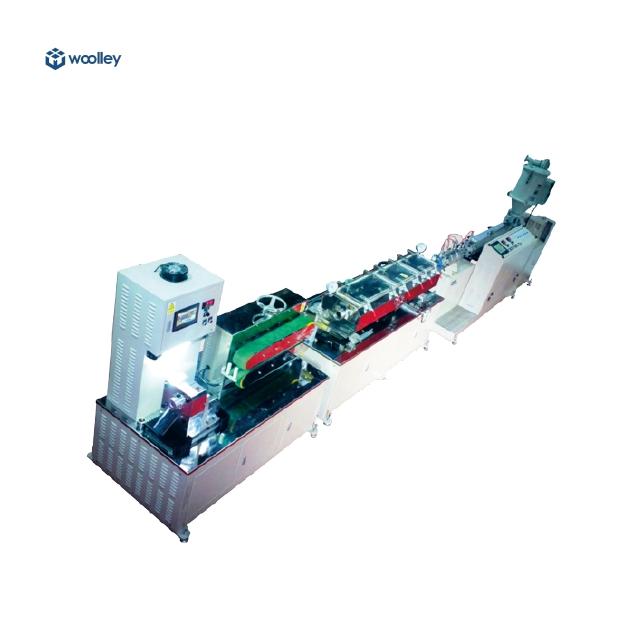

In the fast-paced world of manufacturing, staying ahead of the competition requires constant innovation and the adoption of cutting-edge technology. For businesses involved in tube extrusion, upgrading your tube extrusion machine can be a game-changer. Whether you're looking to improve efficiency, enhance product quality, or reduce downtime, choosing the right machine upgrade is crucial. Woolley Automatic Machinery Ltd, a leading name in the industry and renowned for its Quicker Tube Machines, offers a comprehensive range of solutions to meet your needs. In this article, we’ll dive into the key factors to consider when upgrading your tube extrusion machine and how Woolley Automatic Machinery Ltd can help you achieve your goals.

Before delving into the specifics of what to look for, it’s important to understand why upgrading your tube extrusion machine is a worthwhile investment. The manufacturing landscape is evolving rapidly, with increasing demands for precision, efficiency, and sustainability. An outdated machine can hinder your ability to meet these demands, leading to higher operational costs, lower productivity, and compromised product quality.

Upgrading your tube extrusion machine offers several benefits:

Enhanced Efficiency: Modern machines are designed to operate faster and more efficiently, reducing production time and energy consumption.

Improved Product Quality: Advanced technology ensures consistent and precise extrusion, resulting in higher-quality tubes.

Reduced Downtime: Newer machines are more reliable and require less maintenance, minimizing unexpected interruptions.

Adaptability: Upgraded machines can handle a wider range of materials and tube sizes, enabling you to diversify your product offerings.

Compliance: Modern equipment often meets the latest industry standards and regulations, ensuring your operations remain compliant.

With these benefits in mind, let’s explore the key factors to consider when upgrading your tube extrusion machine.

The first step in choosing the right upgrade is to assess your current and future production needs. Consider the volume of tubes you need to produce and whether your existing machine can meet this demand. Woolley Automatic Machinery Ltd’s Quicker Tube Machines are designed to handle high production volumes without compromising on quality. Their advanced automation features allow for faster production cycles, enabling you to meet tight deadlines with ease.

Different industries require tubes made from a variety of materials, such as aluminum, stainless steel, or plastic. Your upgraded machine should be capable of handling the materials you work with. Quicker Tube Machines from Woolley Automatic Machinery Ltd are known for their versatility, offering compatibility with a wide range of materials. This flexibility ensures that you can cater to diverse customer requirements and expand your market reach.

Precision is a critical factor in tube extrusion, especially for industries like aerospace, automotive, and medical, where even the smallest deviations can have serious consequences. Look for machines equipped with advanced control systems that ensure consistent extrusion and minimal dimensional variations. Woolley Automatic Machinery Ltd integrates state-of-the-art technology into their Quicker Tube Machines, guaranteeing high levels of precision and accuracy.

Automation is no longer a luxury but a necessity in modern manufacturing. Automated tube extrusion machines not only improve efficiency but also reduce the risk of human error. Woolley Automatic Machinery Ltd’s Quicker Tube Machines come with advanced automation features, including real-time monitoring, automatic adjustments, and seamless integration with other production equipment. These capabilities streamline your operations and enhance overall productivity.

Energy costs are a significant expense for manufacturing businesses. Upgrading to an energy-efficient tube extrusion machine can lead to substantial savings in the long run. Woolley Automatic Machinery Ltd prioritizes sustainability, designing their Quicker Tube Machines to consume less energy while maintaining optimal performance. This not only reduces your operational costs but also aligns with environmental regulations and corporate sustainability goals.

Maintenance is an inevitable part of machine operation, but it doesn’t have to be a hassle. Choose a machine that is easy to maintain and comes with comprehensive support from the manufacturer. Woolley Automatic Machinery Ltd offers robust after-sales service and readily available spare parts for their Quicker Tube Machines, ensuring minimal downtime and maximum uptime.

Every business has unique requirements, and a one-size-fits-all solution may not be ideal. Look for a manufacturer that offers customization options to tailor the machine to your specific needs. Woolley Automatic Machinery Ltd excels in providing bespoke solutions, allowing you to choose features and configurations that align with your production goals.

While the upfront cost of upgrading your tube extrusion machine may seem high, it’s essential to consider the long-term return on investment (ROI). A high-quality machine from Woolley Automatic Machinery Ltd can pay for itself through increased efficiency, reduced maintenance costs, and improved product quality. Take the time to calculate the potential ROI and weigh it against the initial investment.

When it comes to upgrading your tube extrusion machine, Woolley Automatic Machinery Ltd stands out as a trusted partner. Here’s why:

Industry Expertise: With years of experience in the field, Woolley Automatic Machinery Ltd understands the unique challenges and requirements of tube extrusion.

Innovative Solutions: Their Quicker Tube Machines are equipped with the latest technology, ensuring top-notch performance and reliability.

Customer-Centric Approach: Woolley Automatic Machinery Ltd takes the time to understand your needs and provides tailored solutions that deliver value.

Comprehensive Support: From installation to maintenance, their team is committed to providing exceptional support throughout the machine's lifecycle.

Global Reach: As a leading manufacturer, Woolley Automatic Machinery Ltd serves clients worldwide, ensuring access to their cutting-edge products and services.

Upgrading your tube extrusion machine is a strategic decision that can have a profound impact on your business. By considering factors such as production capacity, material compatibility, precision, automation, energy efficiency, and maintenance, you can choose a machine that meets your current and future needs. Woolley Automatic Machinery Ltd, with its Quicker Tube Machines, offers the perfect combination of innovation, reliability, and customer support to help you stay ahead in the competitive manufacturing landscape.

Don’t let outdated equipment hold you back. Contact Woolley Automatic Machinery Ltd today to explore their range of Quicker Tube Machines and take the first step toward a more efficient and profitable future.

Tags:Auto Foiling Capping Machine,Auto Boxing Packing Machine,Dry Offset Printing Machine,PET Cans machine line

Contact: Mr. Woolley Tian

Phone: +8613671872020

Tel: +8613671872020

Email: woolley@woolleyauto.com(Вудли)

Add: No. 1379, Jiahao Road, Nanxiang Town, Jiading District, Shanghai City, China.